Multifunction Laboratory Mixers

- Availability: On Order

- Brand: Armfield

- Product Code: FT141/FT142

- Product viewed: 36382

Share:

Multifunction Laboratory Mixers

MINIATURE-SCALE R&D TECHNOLOGY

FT141/142 Multifunction Laboratory Mixers

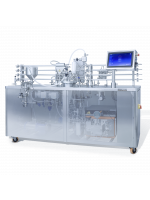

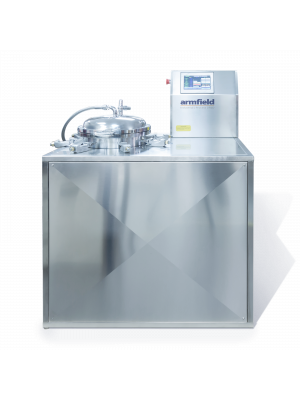

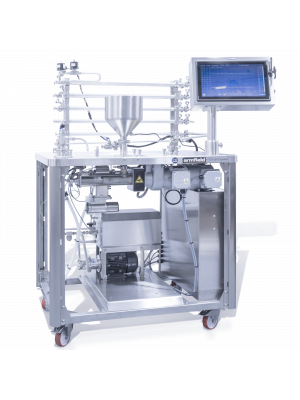

The Armfield FT141 and FT142 are versatile batch processing vessels, the FT142 having UHT capability. They are suitable for high shear mixing, dispersing, homogenising, emulsifying, evaporation and vacuum deaerating.

Features

• 10 or 20 litre product capacity

• High speed bottom mounted emulsifying mixer

• Top mounted gentle agitator with flexible scraper

• Simultaneous high shear mixing and sidewall agitation

• Vacuum capability

• Powered lift for tank lid

• Inlet funnel and valve

• FT142 has UHT Capability: 140°C, 3 bar

• Large diameter hygienic outlet valve

• Full instrumentation

• Jacketed vessel for indirect heating and cooling

•Optional direct heating using steam

• Viewing window with light and wiper

• Range of process options

Benefits

> Representative results from small quantities of product

> Maximum flexibility allows development of a wide range of products

> Fast emulsifying for improved dissolving of powders

> De-aeration with vacuum

> Straightforward scale up

> Simple to use

Description

The FT141 and FT142 are multifunction batch process systems designed for the hygienic processing of up to either 10 or 20 litres of product, depending on the option selected. Each system comprises of the jacketed mixing tank, a high speed mixer, a gentle agitator, a vacuum system, steam heating and water cooling of the jacket, water flush for the shaft seals and an electronic control panel. Direct steam heating of the vessel can be provided as an option.

The FT141 is capable of processing at 95% vacuum and up to 100°C temperature. The FT142 extends the performance into UHT processing at up to 140°C and 3 bar pressure.

Each tank is fitted with a large diameter (51mm) manual outlet valve and a 25mm manual inlet valve complete with inlet funnel. All contact surfaces are 316 Stainless Steel. The vessels are equipped with a temperature sensor, a safety cut-out switch and a sight glass with a light and wiper. The clamped lid has a powered lift mechanism for easy raising. The heating/cooling jacket can be pressurised and is fitted with a safety valve.

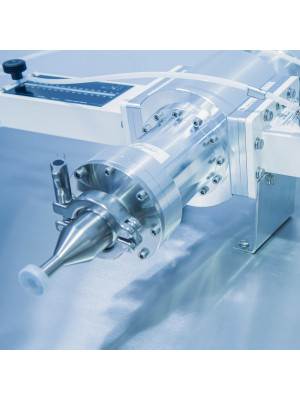

A high speed mixing head with variable speed control is provided in the bottom of the vessel, carefully positioned in relation to the outlet valve to allow easy drainage. The standard mixing head is a double bladed knife. Other heads can be provided on special request, such as single knife or a mixer with a stator ring. Stator rings are available with different hole sizes from 1mm up.

A slow speed gentle agitator is fitted on the vessel lid. This is a double arm agitator with a flexible scraper on one arm to prevent burn on of the product to the side of the vessel.

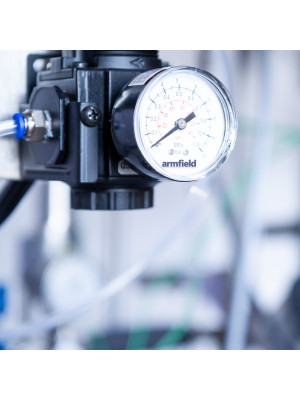

A liquid ring vacuum pump is used when required to process below atmospheric pressure. A combined pressure and vacuum gauge is used to display the tank pressure. The FT142 includes a cooler on the connecting pipe to the vacuum pump. Options are available for automatic vacuum control and for a condensation collector with a sight glass in the vacuum line.

The mechanical seals on the rotating shafts are automatically flushed with water via a solenoid valve, activated together with the motors.

The electronic control panel is enclosed to IP54 standard and made of 304 grade stainless steel. It includes start/stop controls and speed controls for the motors, temperature display, heating and cooling set points, plus emergency stop. Once the heating set point has been reached the temperature is maintained using on/off control.

Unit Specifications

FT141

Mixer Speed: Variable to 3,000 rpm

Agitator speed: Variable to 36 rpm

Maximum Vacuum: -950 mbar Gauge

Jacket Pressure: 4 bar max

Maximum Temperature: 100°C

Tank Insulation: 30mm

FT142

Mixer Speed: Variable to 3,000 rpm

Agitator speed: Variable to 36 rpm

Maximum Vacuum: -950 mbar Gauge

Jacket Pressure: 4 bar max

Maximum Temperature: 140°C

Tank Insulation: 30mm

Order Codes

FT141-10: Ten Litre Multifunction Laboratory Mixer

FT141-20: Twenty Litre Multifunction Laboratory Mixer

FT142-10: Ten Litre UHT Multifunction Laboratory Mixer

FT142 -20: Twenty Litre UHT Multifunction Laboratory Mixer

Options

FT141-11/FT142-11 PLC control system with 6” (153mm) colour touch screen

FT141-12/FT142/12 Automatic vacuum control valve

FT141-13/FT142-13 Direct Steam Injection connection with valve

FT141-14/FT142-14 Water inlet to prove a measured quantity of water into the vessel, selectable in increments of 0.25l

FT141-15/FT142-15 Condenser and sight glass on vacuum pipe

FT141-10-16/FT142-10-16 Safety shield for 10l tank lid

FT141-20-16/FT142-20-16 Safety shield for 20l tank lid

Additionally extra sockets can be provided for additional instrumentation.

All options must be specified at time of order.

Voltage Options

FT141-10-E/FT141-20-E } 380-415V/3ph/50Hz

FT142-10-E/FT142-20-E }

FT141-10-D/FT141-20-D } 208-220V/3ph/60Hz

FT142-10-D/FT142-20-D }

Requirements

Steam Supply:

Steam (indirect heating) 13Kg/hr max at 4 bar

Steam (direct heating) 75Kg/hr max at 4 bar

Compressed Air:

Compressed air 100l/min max at 6 bar

Water:

Water 8.5l/min at 4 bar constant pressure

Electricity:

Electricity three phase 6KW max (400V version runs off a standard 16A supply)

Shipping Specification

Volume: 5.7m³

Gross weight: 910kg

Overall Dimensions

Height: 1.75m (2.15m lid open)

Width: 1.7m

Depth: 1.3m