Edible Oils

Edible oils production in the laboratory with Technolab. We supply a complete line for the production of edible oil from a range of fruits, nuts and seeds in laboratory scale batches of approximately 20 kg.

Edible oil is washed out of oily seeds by a solvent using a solid-liquid extraction process (FT29). Raw cooking oil is refined by the FT66 Neutralizer / Scrubber / Bleacher. The deodorizing unit FT68 is used for final processing. The FT67 hydrogenation unit is used to remove possible traces of catalysts.

Further processing can be carried out with our suitable equipment such as homogenizers, process tanks and margarine machines.

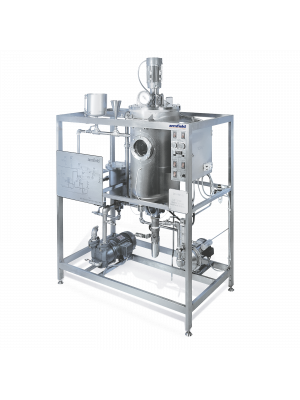

FT29 Batch Solvent Extraction and Desolventising Unit The Armfield Batch Solvent Extraction and Desolventising Unit is a floor-standing, ..

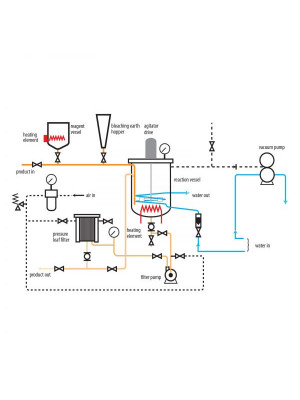

Das Standmodell Armfield FT66 Neutralisator/Wäscher/Bleicher für die Batchverarbeitung ist in der Lage, die Vor-Raffinationsstufen für kleine Mengen v..

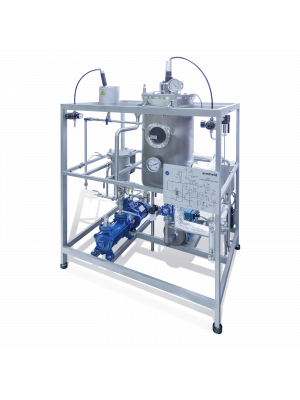

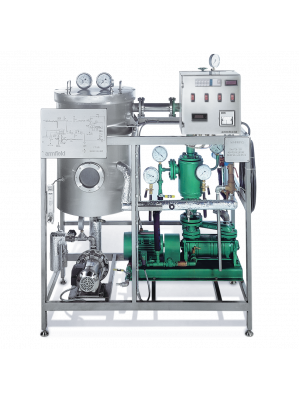

MINIATURE-SCALE R&D TECHNOLOGYFT67 Hydrogenation UnitThe Armfield Hydrogenation unit is a floor-standing batch processing vessel, which is used to..

MINIATURE-SCALE R&D TECHNOLOGYFT68 Deodorising Unit The Armfield Deodorising Unit is a floor-standing batch processing vessel suitable for steam s..